TYRANNOSAURUS® system

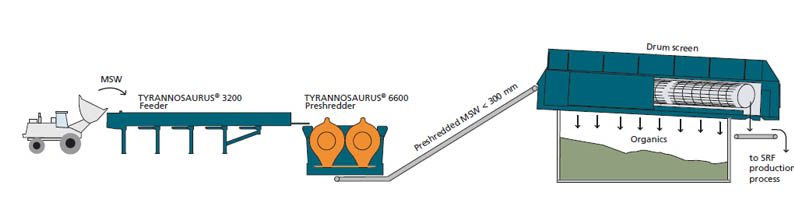

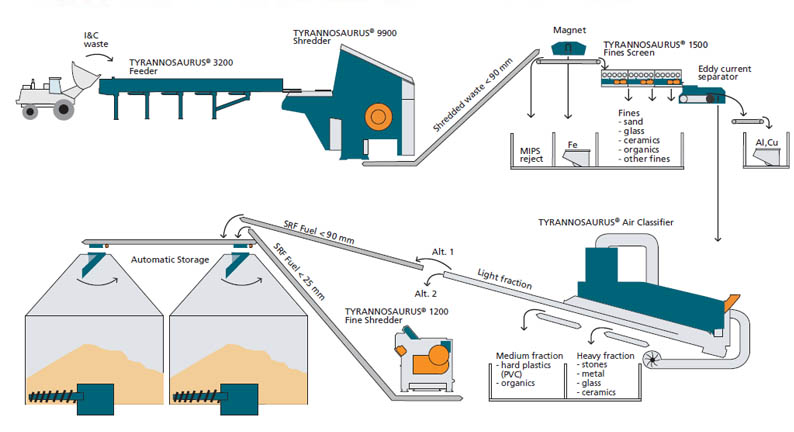

The process starts with the raw material in the feeder. Tyrannosaurus Feeder is automatized to work optimally together with the shredder. If the shredder has a big mouthful to chew, the feeder slows down, allowing the production line always to work at maximum capacity. Tyrannosaurus Shredder is simply the biggest, strongest and smartest shredder in the world. He weighs up to 90 tonnes, is made of a 60 mm solid steel frame and never stops working. Not only is he robust, but he is intelligent, too: MIPS® (Massive Impact Protection System) means that he will spit out bigger pieces of metal that cannot be crushed and keep on shredding. And shred he will. At maximum capacity, he can reduce particle size to 75 mm in one single stage. ZeroGap® shredding means that particle size and quality are maintained even with the wear of knives. The knives are hydraulically adjustable to keep on working optimally and to lengthen the service interval. After ferrous metals have been separated by belt magnets, Tyrannosaurus Fines Screen separates sand, glass, soil, organics and other small heavy and wet particles. This is followed by separating conductive metals by eddy current separators. The final touch is given by Tyrannosaurus Air Classifier. This is the decisive stage concerning the quality of the fuel. In the Tyrannosaurus System, you can adjust the process online, allowing you to make the optimal fuel for the end user, for example cement kiln or power plant. Should smaller particle sizes (20 – 25 mm) be needed, Tyrannosaurus Fine Shredders – the biggest in the world – can be added to the production line.